Critical minerals play a very important role in renewable energies and batteries, making them one of the pillars of the energy transition. Therefore, today we cannot think about the energy transition without considering critical minerals.

What are critical minerals?

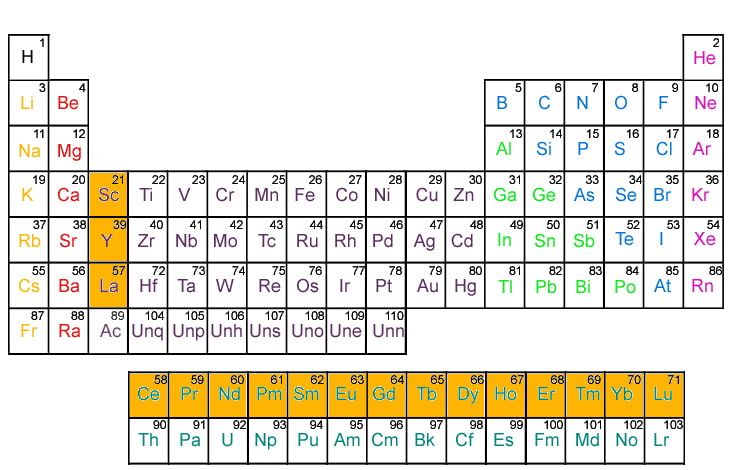

Critical minerals are the 17 elements of the periodic table in the group of lanthanides, actinides, scandium and yttrium. The concentration of these elements in the earth’s crust is rare and a more complex extraction process is required to obtain a small amount.

Critical minerals in the periodic table. Source: ECyTHistory of critical minerals

Critical minerals in the periodic table. Source: ECyTHistory of critical minerals

In 1787 Carl Axel Arrhenius discovered an unknown mineral in a village in Ytterby, Sweden. This ore contained several rare elements that later became known as “critical minerals”.

In the 20th century, these elements were discovered to have magnetic properties and began to be used for different purposes. At the beginning of the 21st century, the development of technology led to an increase in demand for critical minerals.

Major critical minerals deposits

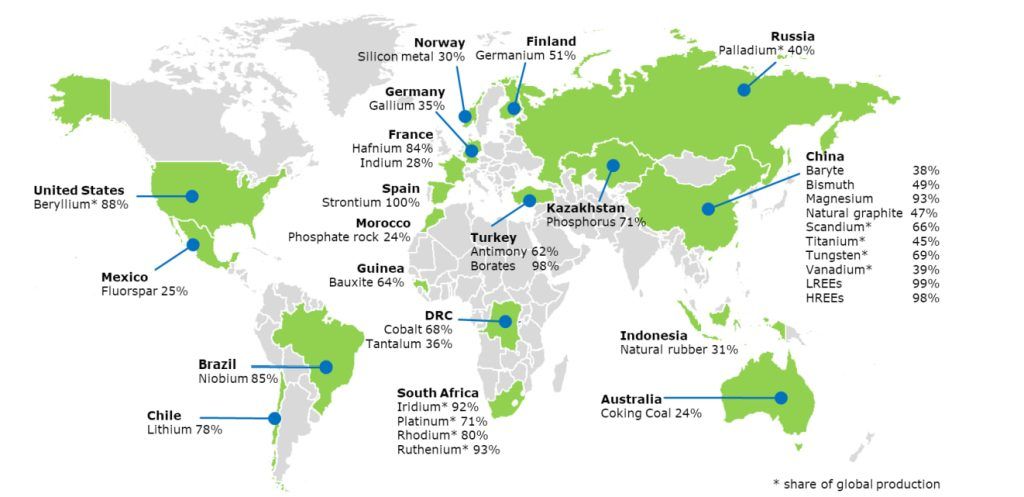

Critical minerals deposits are distributed in different regions of the world. This distribution is one of the main problems of these elements, giving power to the countries that have them.

The countries that have the most important deposits are:

- China: the world’s leading producer of critical minerals, with one of the largest deposits in Bayan Obo. China has invested heavily in the extraction and processing of critical minerals, which has given it a dominant position.

Bayan Obo mine. Source: ejatlas

Bayan Obo mine. Source: ejatlas

- United States: has several important critical minerals deposits, but production has declined in recent years. The Mountain Pass deposit in 2020 produced 15.8% of world production. The mine closed in 2002 because of environmental regulatory pressure. Mountain Pass reopened a few years later, but could not withstand strong competition from Asia and closed in 2017.

- Russia: has significant critical mineral deposits, including the Lovozersky deposit.

Other countries with significant deposits include Australia, India, Brazil, Malaysia, Vietnam, South Africa, Canada and Greenland.

In the European Commission’s list of critical materials (materials at risk of supply), it is easy to see which countries have the largest production of these critical minerals.

Countries accounting for largest share of EU sourcing of Critical materials. Source: European Commission

Extraction of critical minerals and their contamination

Critical minerals are extracted from deposits using various techniques depending on the type of mineral and the location of the deposit. The most common techniques are:

- Open-pit mining

- Underground mining

- Drilling

- Fracking

- In situ mining

Once they have been extracted, they are subjected to separation and refinement processes to obtain the compounds and oxides that will be used in their various applications.

This extraction, separation and refining process can have a negative impact on the environment if strict environmental controls are not followed. This is the case in less strict countries such as Asia, where the extraction of critical minerals generates a considerable environmental impact.

The pollution associated with critical minerals mining is described below:

- Water pollution: during the extraction and processing process, chemicals are used that can leach into the ground and reach underground and surface sources, affecting water quality. Other liquid wastes such as sludge may contain toxic elements and heavy metals that pose a risk to aquatic life and human health.

- Soil contamination: In order to extract critical minerals, a large amount of soil and rock must be removed, which implies the destruction of the terrestrial ecosystem. In addition, the aforementioned chemicals can leach into the soil, affecting soil capacity, local ecosystems and agricultural production.

- Generation of toxic waste: waste from critical mineral mining contains radioactive elements, heavy metals and chemicals. Failure to handle these substances correctly can damage the ecosystem of the area.

- Greenhouse gas emissions: Extraction and processing is energy-intensive and results in high greenhouse gas emissions.

These impacts have caused many countries to reduce their production of critical minerals and opt to cover their needs with production in other countries. In the case of China, the main producer, less rigid environmental regulation poses a greater danger to the overall impact.

Main uses of critical minerals in energy

- Photovoltaic solar panels:

Critical minerals play a key role in the production of photovoltaic cells, which are the fundamental components of solar panels.

One of the most widely used critical minerals elements in photovoltaic cells is silicon. Silicon doped with small amounts of critical minerals elements, such as gadolinium or praseodymium, can improve the efficiency of sunlight absorption.

In addition, research has been carried out to use other critical minerals elements in photovoltaic cells, such as tellurium and germanium. These elements can further improve conversion efficiency and enable the production of more efficient and cost-effective solar panels.

- Wind turbines:

In wind turbines, neodymium-iron-boron magnets, which contain critical minerals elements such as neodymium and dysprosium, are used. These magnets are essential for electricity generation in high-efficiency wind turbines. Critical minerals magnets have superior magnetic properties, such as high coercivity and high Curie temperature, allowing for the generation of stronger magnetic fields and higher energy conversion efficiency.

- Batteries:

Critical minerals are used in Lithium-ion batteries and Nickel-Metal Hydride batteries.

Lithium-ion batteries are widely used in a variety of applications, from portable electronic devices to electric vehicles and large-scale energy storage systems. These batteries are known for their high energy density, long life and rechargeability.

In lithium-ion batteries, critical minerals play a key role in the composition of the cathodes and electrolytes. The cathodes of lithium-ion batteries are typically composed of transition metal oxides, such as cobalt, nickel and manganese. Critical minerals, such as lanthanum, cerium and praseodymium, are used as additives in the cathodes to improve the charging and discharging efficiency of the battery.

These critical minerals additives help stabilise the cathode structure, improve ionic conductivity and reduce material degradation during charge and discharge cycles. As a result, lithium-ion batteries containing critical minerals can have higher storage capacity, greater energy efficiency and longer lifetimes.

Nickel-metal hydride (Ni-MH) batteries are another rechargeable battery technology widely used in electronic devices, power tools and hybrid vehicles. These batteries offer a more environmentally friendly alternative to nickel-cadmium batteries, as they do not contain toxic materials.

Critical minerals, such as lanthanum and neodymium, are used as additives in the metal hydride alloy, which acts as the anode in the battery. These critical minerals additives help to increase the hydrogen storage capacity of the anode, which results in higher battery capacity and energy efficiency.

In addition, critical minerals can also improve the corrosion resistance and thermal stability of the Ni-MH battery, which contributes to longer life and better performance in adverse conditions.

- Electric vehicles:

Neodymium-iron-boron (NdFeB) permanent magnets, which contain critical minerals elements such as neodymium, are used in electric vehicle traction motors. These magnets generate a strong and stable magnetic field, which allows for higher motor efficiency and performance. Critical minerals magnet traction motors are more compact, lighter and more efficient compared to conventional motors, which contributes to improving the range and energy efficiency of electric vehicles.

Critical minerals can also be found in the magnets and coils of power converters to improve the efficiency and performance of electric vehicle propulsion systems.

Critical minerals challenges

One of the main challenges is that China is the world’s leading producer and exporter of critical minerals, leading to direct concerns regarding security of supply and price volatility. These fluctuations directly affect the viability of renewable and battery projects, which could put a brake on the energy transition.

A key strategy to ensure the sustainability of critical minerals is the diversification of supply sources. Rather than relying heavily on a single country or region, new sources of critical minerals need to be sought and developed in different parts of the world. By making production more “local”, it is possible to keep more control over the environmental impact that is being caused.

On the other hand, the environmental impact of critical minerals must be controlled by strict regulation to minimise the environmental impact. In addition, the transport of critical minerals also involves a significant environmental footprint.

Research and development of alternatives and substitutes to critical minerals in both renewable energy and batteries is currently being promoted. These other materials could reduce the dependence that currently exists and even reduce the environmental impact they produce.

Ultimately, recycling and reuse of critical minerals are essential to reduce the impact and dependence on new extraction of critical minerals.

Agnès Lomascolo | Energy consultant at Magnus Commodities

If you found it interesting, please share it!

Recent Articles